Personnel and speed savings are achieved by using sorter systems for a large number of distribution points and high speed shipments.

- During the design phase of the sorter system, our customers are presented with the number of distribution points they will need, the amount of warehouse space, the number of personnel, and the delivery times per hour by preparing simulation programs.

- After the simulation, parameters such as hourly box entry and exit numbers, durations, number of personnel will be clarified and committed to the main customer.

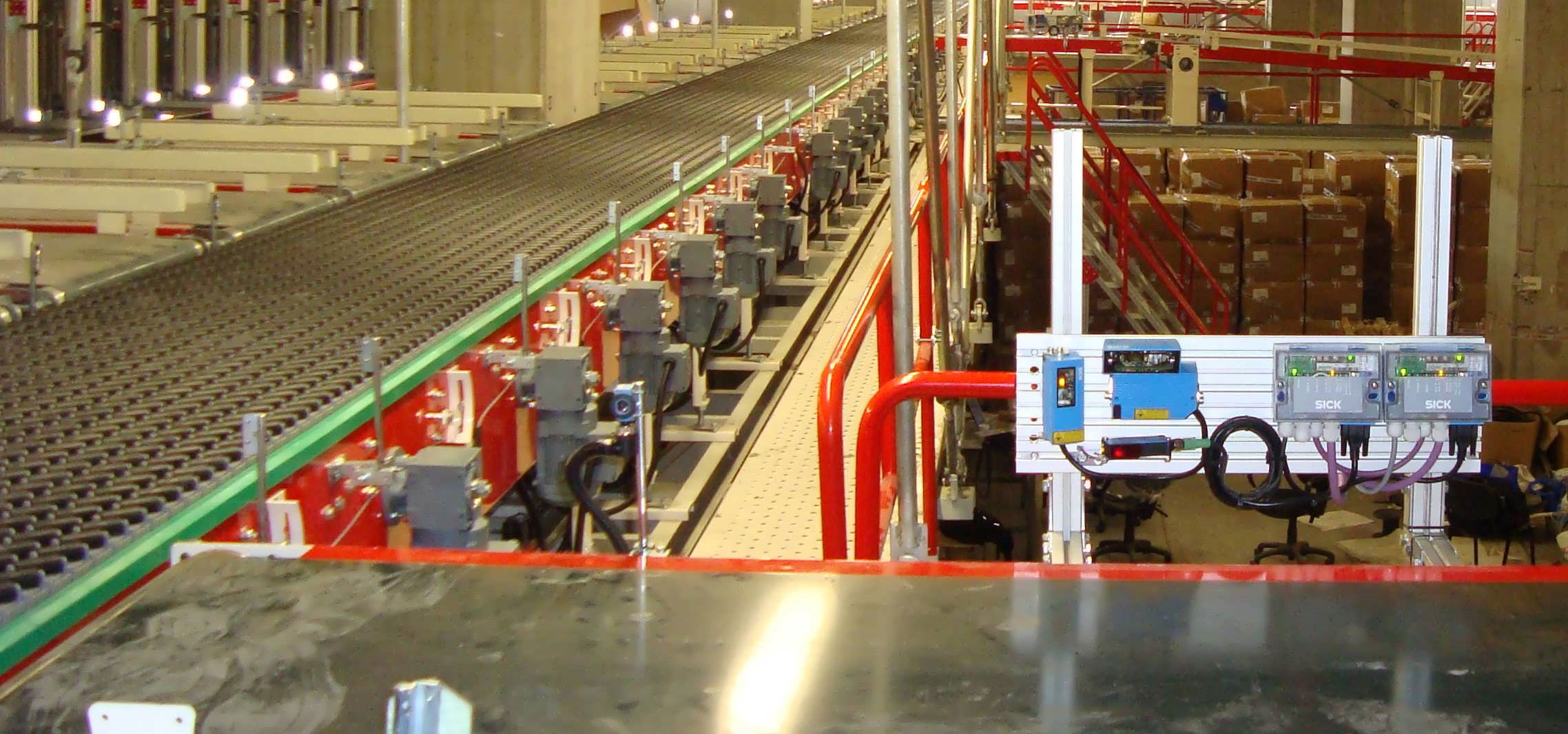

- The design decided after the simulation is manufactured in our workshops and integrated into the warehouse area.