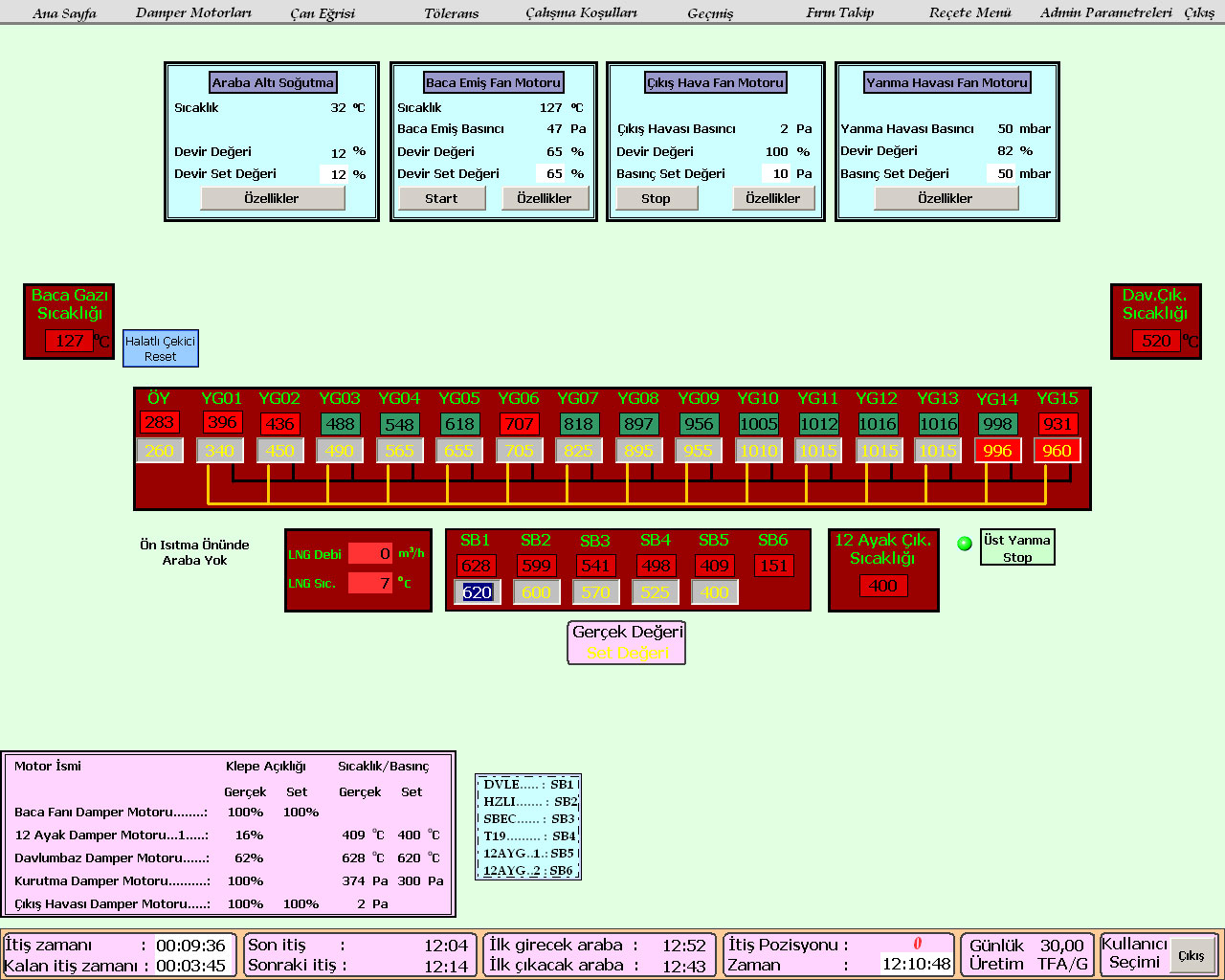

In furnaces that have been operating for many years, the automation group boards and equipment that have expired are replaced with new and state-of-the-art products, and the software is re-prepared according to new needs.

- In furnaces that have been operating for many years, the automation group boards and equipment that have expired are replaced with new and state-of-the-art products, and the software is re-prepared according to new needs.

- Energy efficiency is controlled by the new software prepared, necessary arrangements and improvements are made in the system.

- Thanks to the reporting facility, the temperatures, date and customer of the product are recorded.