In the presses that have been operating for many years, the panel and equipment of the automation group that have expired are replaced with new and state-of-the-art products, and the software is prepared again according to new needs.

Sample Projects

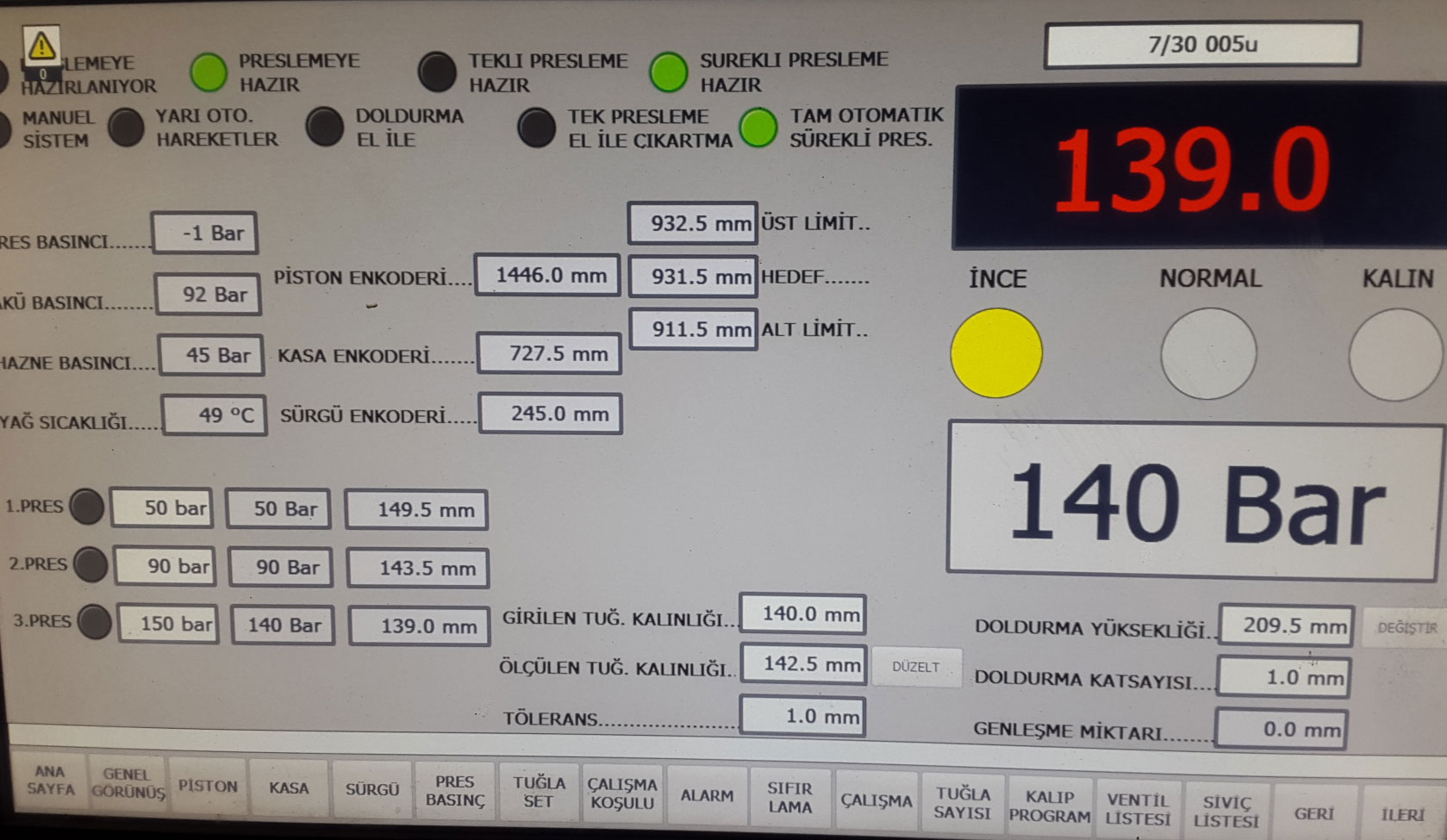

Press Modernization (Refrakter Brick Industry)